Behind the Scenes at Sapphire Creative: How We Print Custom Apparel

- Sapphire Creative

- Dec 4, 2025

- 4 min read

Ever wonder what goes into creating your custom hoodies, embroidered hats, or team uniforms?

At Sapphire Creative, every order goes through a hands-on, high-quality production process that combines precision, creativity, and care. Whether you’re a business owner in Chilliwack or part of a school team in the Fraser Valley, we thought you might like a peek at what actually happens behind the scenes.

Let’s walk you through how we bring custom apparel to life — from logo setup to final stitch.

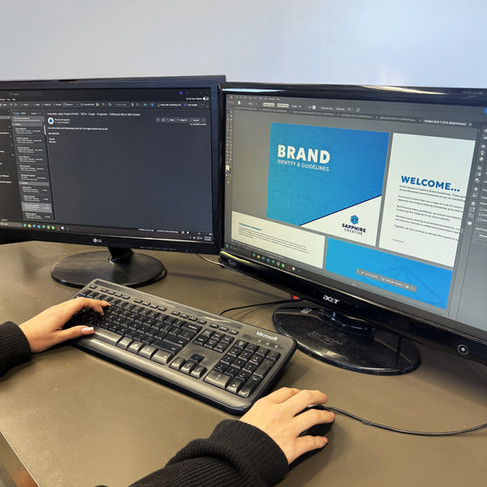

Step 1: Prepping Your Design

Everything starts with your logo or artwork. If it’s not yet ready for print, we help clean it up or convert it into a proper format. For embroidery, this means digitizing your logo — translating it into a special file that tells the machine where every single stitch goes.

Need help with this? We’ve got you covered.

Not sure if your file is usable? Send it in and we’ll take a look.

Step 2: Custom Apparel Printing Methods We Use

We don’t just slap a logo on a hoodie and call it a day. We look at:

· Fabric type (cotton, polyester, fleece, blends)

· Logo size and detail

· Use case (indoor, outdoor, uniforms, events)

Then we match your project to the best production method:

Embroidery: Best for hats, polos, jackets, and uniforms. Clean, durable, and professional.

Screen printing: Great for bold designs on t-shirts and hoodies.

Direct-to-film (DTF): A flexible option for full-color artwork on all fabric types.

Each technique has its strengths — and we’ll help you choose the one that fits your needs, budget, and brand style.

Step 3: Machine Setup and Calibration

This is where the magic starts.

Our team threads the embroidery machine, aligns each garment, and sets everything to precise measurements. For screen printing, we prep custom screens for each ink color. For DTF, we ensure artwork is transferred perfectly before heat pressing.

Our equipment may be high-tech, but our approach is still hands-on.

Every project is checked, adjusted, and prepped by real people — not robots.

Step 4: Production in Action

This is the fun part — watching your logo come to life. Whether it’s an embroidery needle running at 1,000 stitches per minute or a vibrant screen print layering color after color, we monitor every pass to ensure sharpness, alignment, and consistency.

Nothing gets through without a quality check.

Step 5: Finishing and Delivery

Once your order is printed or stitched, we trim any loose threads, steam the garments (if needed), fold everything neatly, and package it for pickup or delivery.

This is where it all comes together — a professionally finished product you’ll be proud to hand out, wear, or showcase.

Popular Custom Apparel Projects We See

We love seeing the variety of projects that come through the studio — here are some common ones:

· Branded hoodies for local businesses and trades

· Embroidered hats and polos for company uniforms

· School spirit wear and grad gear

· Team apparel for soccer, hockey, and baseball clubs in Chilliwack

· Event shirts, staff gear, and community merch

No matter the project, we’re here to make your team look good.

The Sapphire Creative Difference

We’re not an online print warehouse — we’re a local print shop that believes in custom, thoughtful production. From your first email to final pickup, everything is done with intention and attention to detail.

Our Chilliwack-based team works with schools, trades, small businesses, and community organizations across the Fraser Valley — and we treat every order like it matters (because it does).

We don’t cut corners. We build brands.

Want to Create Something Custom?

If your business, school, or team is ready for custom apparel that fits your brand and your goals — we’d love to help.

Explore our custom apparel options or book a consultation with our team to get started.

Here is to fresh prints, clean stitches, and gear that makes your team feel proud. 🚀

— The Sapphire Creative Team

Frequently Asked Questions

1. Where can I get custom apparel printed in Chilliwack?

You can get high-quality custom apparel printed at Sapphire Creative in Chilliwack. We offer embroidery, screen printing, and direct-to-film printing for t-shirts, hoodies, hats, uniforms, and teamwear — all produced in-house with fast turnaround and attention to detail.

2. What’s the best printing method for custom hoodies or uniforms?

It depends on your logo and the type of fabric. Embroidery is perfect for a professional, durable finish on hoodies and polos. Screen printing works well for bold designs on cotton t-shirts. We help Fraser Valley businesses choose the best method for each project.

3. Do I need to send a special file for embroidery or screen printing?

Yes. For embroidery, we’ll need a vector file or digitized design. For screen printing or DTF, a high-resolution logo in PNG, PDF, or SVG format works best. Not sure? Our team at Sapphire Creative can prepare your files for print in our Chilliwack studio.

4. How long does it take to print custom apparel in Chilliwack?

Typical production time for custom apparel is 5 to 10 business days, depending on the quantity and print method. Embroidery may take a bit longer due to setup. We’ll always give you a clear timeline before starting your order.

5. Can I visit Sapphire Creative to discuss a custom apparel project?

Yes! We’re located in Chilliwack and welcome local businesses, schools, and teams to stop by or book a consultation. Whether you need uniforms, event merch, or branded clothing, our team is here to walk you through the process.

Comments